Just How to Identify Common Repair Work Problems in Stretch Wrap Machines and When to Seek Professional Aid

Stretch Wrap equipments are important for efficient packaging operations. They can experience different issues that prevent performance. Operators must be alert in acknowledging indicators of breakdown, such as irregular movie tension or unusual sounds. Comprehending these common fixing issues is vital. Yet, knowing when to look for professional help can make a significant difference. The subtleties of troubleshooting and upkeep deserve checking out even more.

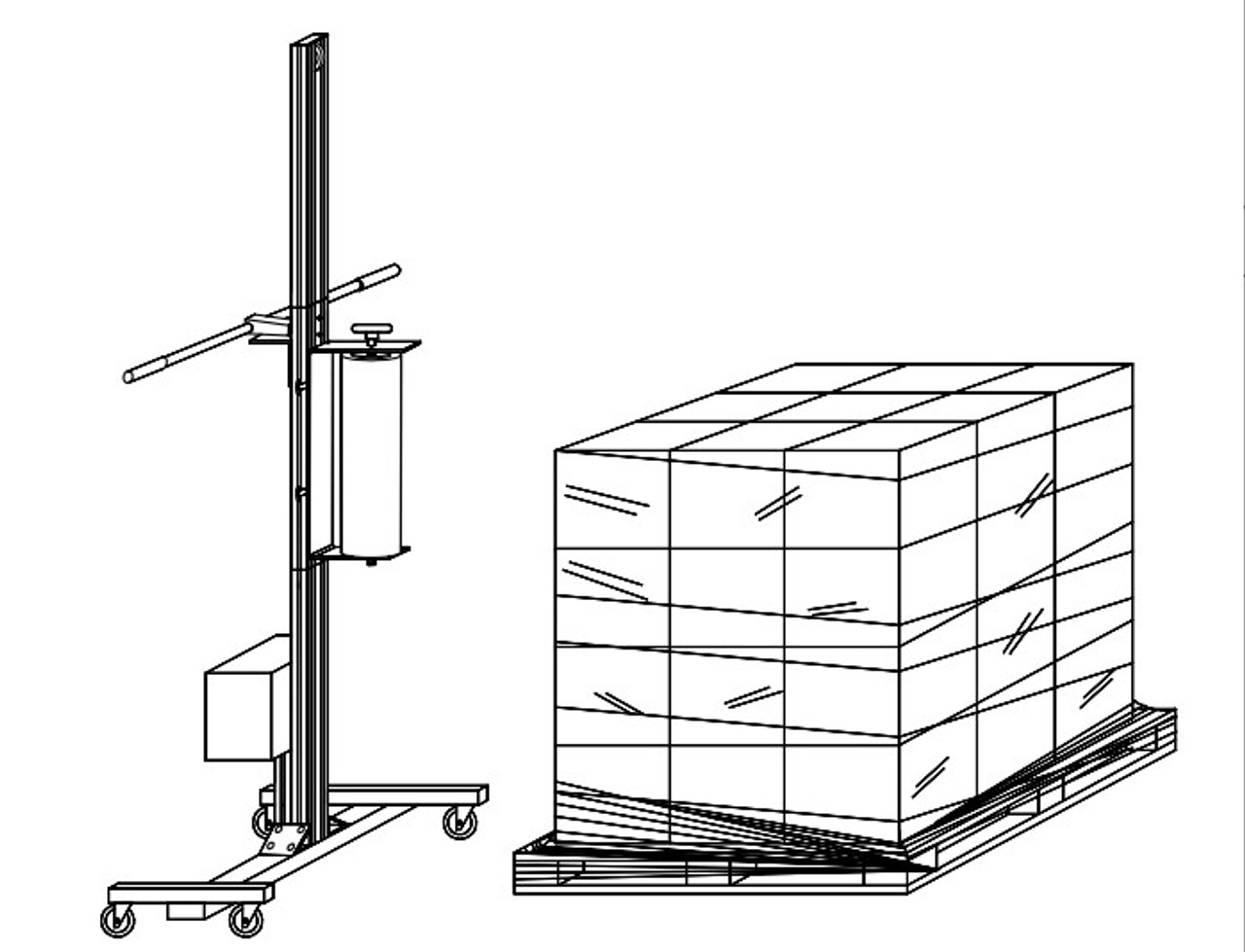

Comprehending the Basics of Stretch Wrap Machines

Stretch Wrap machines are important devices in the product packaging industry, created to firmly envelop items for storage and transport. These makers make use of stretch film, which complies with itself, producing a tight and protective layer around things. Generally, they are available in numerous types, consisting of manual, semi-automatic, and completely automatic models, providing to varied production demands. The operation of a stretch Wrap machine involves feeding the film around the product, applying tension, and sealing the Wrap, making sure that products continue to be steady during transit.Key elements of these machines consist of the movie carriage, turntable, and control panel, each playing an essential role in the covering procedure. Effectiveness is further boosted by adjustable settings that allow users to personalize the tension and number of wraps. Understanding these basics assists drivers optimize the machine's performance, guaranteeing excellent packaging top quality and minimizing the threat of item damage throughout handling or shipping.

Usual Problems With Stretch Wrap Machines

Product packaging efficiency can be greatly endangered by usual issues that occur with stretch Wrap devices. One prevalent trouble is inconsistent film tension, which can bring about poor load stabilization and increased product damage throughout transportation. Furthermore, movie breakage frequently occurs, disrupting the covering procedure and causing hold-ups in operations. One more issue is the inappropriate placement of rolls, which can result in irregular covering and wastage of materials.Malfunctions in the control board may also hinder performance, making it hard to readjust settings or check efficiency. Electrical problems, such as faulty circuitry, can further contribute to functional inefficiencies. Regular upkeep can aid reduce a number of these troubles, guaranteeing the machine runs efficiently. Acknowledging these usual concerns is essential for drivers, as timely intervention can protect against more considerable breakdowns and pricey repairs.

Indicators Your Stretch Wrap Machine Demands Repair Service

When a stretch Wrap machine displays uncommon noises throughout procedure, it may show underlying mechanical issues. In addition, irregular movie stress and regular downtime can further indicate that the device needs instant focus. Identifying these indicators early can assist stop pricey repair work and assure peak performance.

Unusual Noises Throughout Operation

Unusual sounds during operation frequently signal underlying problems with stretch Wrap devices that need instant attention. These noises may include grinding, squealing, or clanking, which can show damage on elements such as equipments, electric motors, or bearings. It may be battling with misalignment or insufficient lubrication if the machine produces unforeseen sounds. Overlooking these audio signs can bring about further damages and expensive fixings. Operators needs to carry out regular assessments to deal with the resource and recognize of the noise quickly. Consulting the equipment's manual can provide details standards for maintenance and troubleshooting. If the problem continues after standard checks, seeking specialist support is a good idea to ensure the machine's longevity and optimal performance.

Irregular Movie Stress

Irregular film tension can significantly influence the efficiency of stretch Wrap machines, bring about substandard tons stability and possible item damages. This concern typically manifests as unequal wraps, where particular areas of the lots are firmly safeguarded while others hang. Operators might discover that the stretch movie is either under-stretched or over-stretched, impacting its capacity to comply with the load. In addition, there might show up signs of moving or slippage throughout transport, suggesting that the film is not offering sufficient assistance. Such inconsistencies can arise from worn-out components, incorrect calibration, or malfunctioning sensing units. Dealing with these concerns promptly is important to guarantee peak maker efficiency and to avoid further difficulties that could occur from poor covering.

Regular Downtime Issues

Constant downtime concerns can signify that a stretch Wrap maker calls for urgent repair. These disruptions usually show underlying mechanical failures or system breakdowns. Operators might see enhanced frequency of jams, which disrupt the wrapping procedure and prevent productivity. Unusual noises throughout operation can also function as red flags, recommending that elements may be misaligned or broken. Furthermore, irregular film application can lead to inadequate load defense, motivating additional operational hold-ups. Disregarding these symptoms might cause much more extreme damages and costly repairs. It is important for operators to check their devices carefully and deal with any kind of indicators of malfunction immediately, ensuring effective procedure and reducing downtime in the long run. Seeking specialist assistance may be essential for complicated issues.

Repairing Minor Problems

Troubleshooting minor issues in stretch Wrap equipments requires a systematic approach to determine and settle concerns successfully. Operators should click for info start by examining the power supply and making sure all links are safe and secure. If the machine does not start, validating the breaker and integrates can often reveal straightforward electric issues. stretch wrap machine repair near me.Next, evaluating the stretch Wrap movie for appropriate placement is necessary. Misalignment can result in uneven covering and may need adjustment of the movie rolls. Furthermore, drivers need to keep track of the tension settings; wrong stress may result in poor Wrap quality.Routine maintenance, such as cleaning up the rollers and guaranteeing they are cost-free from debris, can also prevent small problems from rising. Keeping an eye on the machine's performance can assist in determining patterns that indicate underlying problems. By attending to these small problems immediately, operators can keep peak functionality and stay clear of larger malfunctions

When to Employ a Professional

Operators might discover themselves faced with problems that extend beyond small adjustments and routine upkeep. In such situations, identifying the best minute to contact a professional ends up being crucial. If the stretch Wrap equipment continually stops working to run appropriately in spite of repairing efforts, it may show a much deeper mechanical or electrical mistake. In addition, unusual sounds, persistent mistake messages, or failing to Wrap lots firmly are indicators that know-how is needed.Furthermore, if the device experiences constant breakdowns or if parts are harmed, a professional's intervention is required to stop more difficulties. Operators needs to additionally take into consideration employing aid when unknown with details repair work strategies or when security threats are present. Inevitably, timely specialist support can not only solve complex problems but additionally protect against costly downtime and warranty optimal efficiency of the stretch Wrap machine.

Preventative Maintenance Tips for Stretch Wrap Machines

Often Asked Inquiries

What Is the Typical Life Expectancy of a Stretch Wrap Machine?

Can I Utilize Different Sorts Of Stretch Film on My Maker?

Various kinds of stretch movie can be made use of on an equipment, however compatibility and efficiency might differ - stretch wrap machine repair near me. It's critical to get in touch with the device specs and supplier standards to ensure the most effective outcomes and prevent possible problems

Just How Can I Enhance the Effectiveness of My Stretch Wrap Equipment?

To improve stretch Wrap device efficiency, normal maintenance, perfect film stress setups, proper positioning, and staff member training are essential. In addition, upgrading elements and minimizing downtime via reliable workflow can substantially boost general efficiency and outcome.

Exist Any Kind Of Specific Brands Understood for Integrity?

A number of brand names are recognized for their reliability in stretch Wrap devices, consisting of Signode, Lantech, and Aetna. Individuals commonly commend these producers for their toughness, performance consistency, and solid client assistance, enhancing total operational effectiveness.

What Is the Price Array for Expert Repair Works on Stretch Wrap Machines?

The price array for expert fixings on stretch Wrap equipments differs considerably, usually in between $150 to $1,500, depending on the complexity of the issue, components required, and the technician's expertise associated with the repair procedure. The procedure of a stretch Wrap equipment includes feeding the movie around the product, applying stress, and securing the Wrap, making sure that goods continue to be secure during transit.Key components of these equipments include the film carriage, turntable, and control panel, each playing an important function in the covering process. Inconsistent movie tension can considerably influence the effectiveness of stretch Wrap machines, leading to subpar tons stability and possible product damages. Regular downtime concerns can signal that a stretch Wrap equipment needs urgent fixing. The ordinary lifespan of a stretch Wrap equipment commonly varies from 5 to 15 years, depending on use, upkeep, and the high right here quality of the device. To boost stretch Wrap device efficiency, normal upkeep, excellent movie stress settings, proper positioning, and worker training are vital.